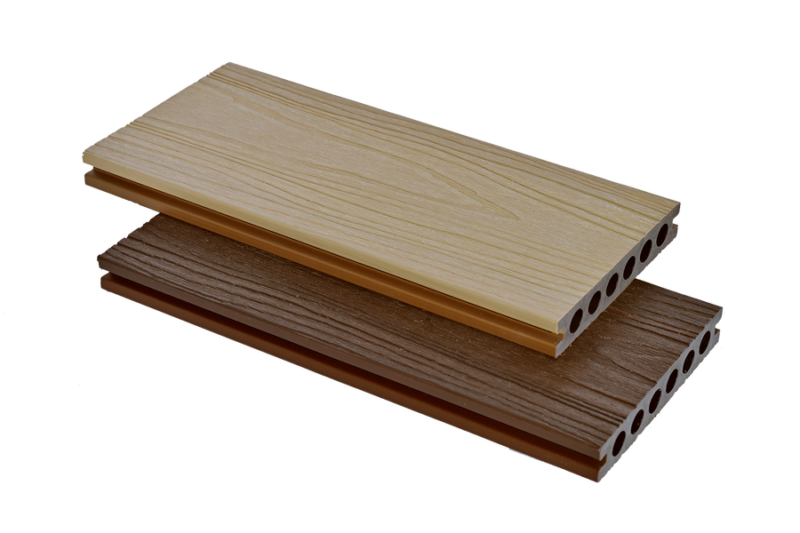

Co-extrusion decking is an advanced version of Wood-Plastic Composite (WPC) decking, offering even greater durability, aesthetics, and performance. It is manufactured using a co-extrusion process, where a protective cap is bonded to the core of the decking during production. This cap layer is made from a highly durable plastic material, offering enhanced protection and resistance to various environmental elements.

Production process

The production process of Co-extrusion Decking utilizes co-extrusion technology, which is an important process in modern composite material manufacturing. The core of this process is to extrude a high-density wood-plastic composite core layer and a weather-resistant plastic outer layer at the same time, and combine them together by heat melting to form a tight overall structure.

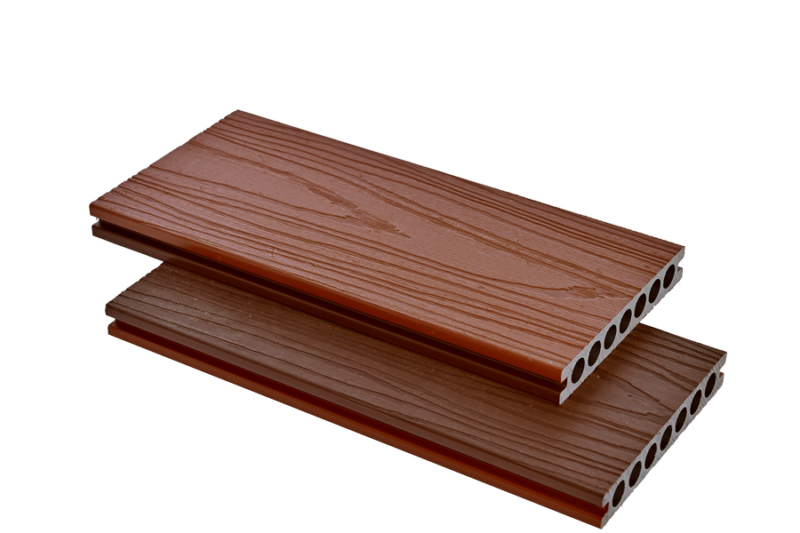

During the co-extrusion molding process, the core layer and outer layer of the wood-plastic composite are extruded at the same time, and the outer layer is firmly wrapped on the surface of the core layer by heat melting. This process ensures that the surface layer is tightly bonded to the core layer and will not delaminate or fall off during subsequent use. After co-extrusion molding, the surface layer can be textured according to design needs, such as adding imitation wood grain or other design textures. This surface treatment not only makes the product closer to natural wood in appearance, but also provides better anti-slip performance.

After extrusion and surface treatment, Co-extrusion Decking will be cooled and then cut into boards of different sizes. These boards are usually further quality tested before packaging to ensure that they meet the standards of durability and appearance.

Application scenarios

Due to its excellent waterproof, anti-fading and durability characteristics, Co-extrusion Decking is widely used in a variety of outdoor environments. The following are some of its typical application scenarios:

1. Home outdoor decks and terraces

Co-extrusion Decking is very popular in home outdoor spaces, especially for terraces, balconies and courtyard decks. These spaces often need to withstand the sun and rain, and traditional wood is prone to cracking, deformation and fading, while co-extruded wood-plastic materials are ideal because of their weather resistance and low maintenance requirements. Its wood grain texture makes the deck beautiful and generous, while its high strength and anti-slip properties ensure safety in use.

2. Areas around swimming pools

Applying Co-extrusion Decking around swimming pools is a very suitable choice, mainly because of its excellent waterproof and anti-slip properties. The swimming pool environment is often in a humid state, and traditional wood is easy to absorb water and cause rot, while the co-extruded outer layer of Co-extrusion Decking can effectively prevent moisture intrusion and extend its service life. At the same time, its surface treatment can provide good anti-slip effect to ensure the safety of users.

3. Commercial plazas and public areas

Co-extrusion wood plastic flooring is widely used in commercial places and public areas, such as restaurant terraces, hotel open-air areas, walkways, seaside walkways and park plazas. Due to the large flow of people in these areas, the floor needs to withstand greater wear and tear, and Co-extrusion Decking is scratch-resistant, stain-resistant and durable, which is very suitable for this high-intensity use environment. Its fade-resistant properties ensure that it can still maintain its beauty after long-term use.

4. Gardens and outdoor landscapes

In courtyard landscape design, Co-extrusion Decking is often used as garden walkways, outdoor seating areas and platform decorations. Because its appearance is close to natural wood and it is not easily affected by weather and pests, it has become an ideal choice to replace traditional wood. In addition, water is often needed to irrigate plants in the garden. The waterproofness of Co-extrusion Decking makes it less susceptible to moisture, avoiding cracking or mold problems caused by water penetration.

5. Roof terraces

In some urban buildings, Co-extrusion Decking is also widely used in roof terraces or roof gardens. As roofs are exposed to various extreme weather conditions (such as heat, UV rays and rainfall), traditional wood and some decking materials have difficulty maintaining their appearance and functionality over the long term. Co-extrusion Decking not only has excellent UV resistance, but is also lightweight and easy to install, making it an ideal material choice for roof terraces on high-rise buildings.