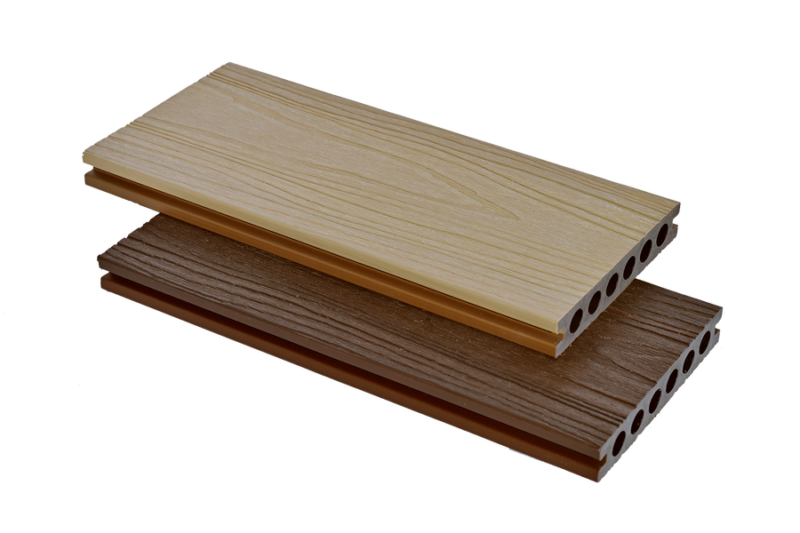

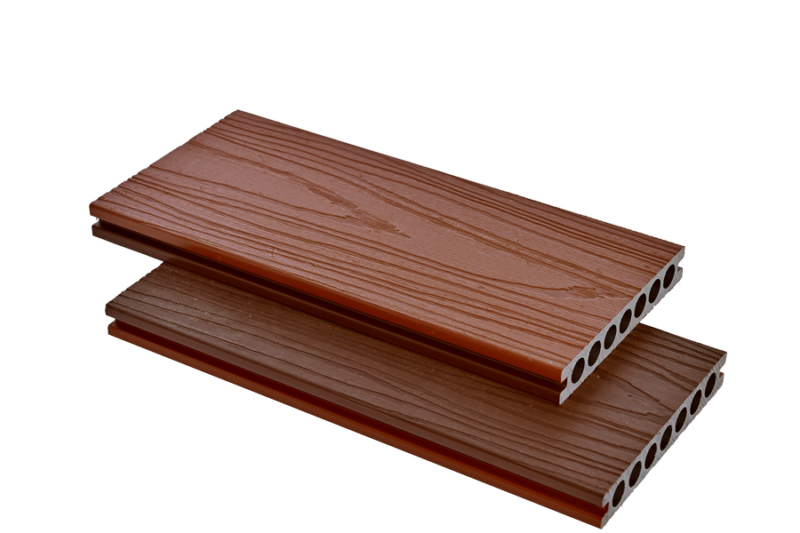

Plastic wood (WPC) profiles have revolutionized outdoor construction, offering a compelling alternative to traditional timber for decking, cladding, fencing, and furniture. Their popularity stems from a blend of wood-like aesthetics, minimal maintenance, and impressive resistance to rot, insects, and weathering. But the performance and longevity of these composite materials hinge critically on the quality and composition of their raw materials. Understanding these building blocks – primarily polymers, wood fibers, and additives – is key to appreciating why plastic wood stands up to the harsh demands of the outdoors.

1. The Polymer Backbone: Strength and Weather Resistance

The plastic component acts as the continuous matrix, binding everything together and providing essential structural integrity, moisture resistance, and weatherability. The choice of polymer significantly impacts cost, performance, and environmental footprint:

Polyethylene (PE): By far the most common, particularly High-Density Polyethylene (HDPE). Sourced primarily from post-consumer or post-industrial recycled streams (like milk jugs, detergent bottles, packaging films), recycled HDPE offers excellent moisture resistance, good impact strength, and relatively low cost. Its widespread use drives the sustainability narrative of WPCs. Low-Density Polyethylene (LDPE) is softer and less rigid but can be blended for specific flow characteristics. Virgin PE is also used, especially where color consistency or higher purity is paramount.

Polypropylene (PP): Offers higher stiffness, heat resistance (reducing thermal expansion/contraction), and better resistance to UV degradation compared to PE. It’s often used in higher-performance decking boards or capstock layers. Virgin PP is more common, though recycled sources are increasing. PP-based profiles generally command a premium.

Polyvinyl Chloride (PVC): Known for its inherent rigidity, excellent weatherability, and fire resistance. PVC-based WPCs (sometimes called “cellular PVC” when foamed) often have a very consistent, non-porous surface, making them highly stain and moisture resistant. They typically use virgin resin and less wood fiber, resulting in a denser, more plastic-like feel but superior performance in consistently wet environments. Concerns about chlorine content and plasticizers can influence choice.

Other Polymers: PET (from recycled bottles) is gaining traction due to its stiffness and clarity, but requires careful processing due to moisture sensitivity and higher melting points. Polystyrene (PS) is less common due to brittleness concerns.

The Polymer Imperative: Regardless of type, the polymer must possess inherent UV stability or be effectively stabilized (see additives). It must also exhibit good melt flow properties for efficient processing and strong adhesion to the wood fibers.

2. The Wood Fiber Core: Stiffness, Aesthetics, and Sustainability

Wood flour or fibers provide the composite with crucial rigidity, dimensional stability (reducing thermal movement compared to pure plastic), and the desired natural wood-like appearance and texture. Their characteristics are vital:

Source Species: Hardwoods (like maple, oak) offer higher density and stiffness but are more abrasive to processing equipment. Softwoods (pine, spruce, fir) are most common due to lower cost, lower abrasiveness, and good reinforcing properties. Bamboo fiber is also used, prized for its hardness and fast growth.

Particle Size and Shape: Finely ground wood flour (typically 40-100 mesh) provides a smoother surface finish and better dispersion within the polymer matrix. Larger fibers or even small wood strands can enhance stiffness but may create a rougher surface. Consistency in size and shape is critical for uniform properties.

Moisture Content: Wood fiber is inherently hygroscopic. It must be dried to very low moisture levels (typically <1-2%) before compounding. Residual moisture turns to steam during high-temperature extrusion, causing voids, surface defects (like bubbling or “freckles”), and reduced mechanical strength.

Purity: Contaminants like bark, dirt, or incompatible glues/resins from recycled wood sources can negatively impact color, processing, bonding, and long-term performance. High-quality wood fiber undergoes rigorous cleaning and screening.

The Wood Fiber Role: Beyond reinforcement, wood fiber lowers the material cost and carbon footprint compared to pure plastic. It also provides the friction needed for safe footing on decking.

3. The Essential Additives: Performance Enhancers and Protectors

Raw polymers and wood alone aren’t sufficient for long-term outdoor performance. A sophisticated blend of additives is crucial:

Coupling Agents: Perhaps the most critical additive. They chemically bridge the hydrophobic (water-repelling) polymer and hydrophilic (water-attracting) wood fiber, dramatically improving bonding strength and interfacial adhesion. This translates directly to higher mechanical strength (especially wet strength), reduced water absorption, and improved durability. Maleated polyolefins (e.g., MAPE, MAPP) are industry standards.

Lubricants (Processing Aids): Reduce friction during compounding and extrusion, improving flow, throughput, surface finish, and reducing wear on machinery. Can be internal (mixed in) or external (applied to the die).

Pigments & Colorants: Provide consistent, fade-resistant color. Inorganic pigments (like iron oxides) offer superior UV stability compared to many organic dyes. Masterbatches (concentrated pigment/polymer blends) ensure uniform dispersion.

UV Stabilizers: Essential for outdoor longevity. Hindered Amine Light Stabilizers (HALS) are predominant, effectively scavenging free radicals generated by UV exposure that cause polymer degradation, fading, and embrittlement. UV absorbers (like benzotriazoles) may also be used. Adequate stabilization prevents the characteristic “chalky” appearance and loss of strength.

Antioxidants: Protect the polymer from thermal and oxidative degradation during high-temperature processing (compounding, extrusion) and long-term service.

Biocides: While the plastic matrix inherently resists rot and insects, biocides are often added, especially in the cap layer (if present) or surface treatment, to prevent mold, mildew, and fungal growth on the surface, particularly in damp, shaded conditions.

Foaming Agents: Used in some profiles (especially PVC-based) to create a cellular core structure, reducing weight and material cost while improving slip resistance and thermal insulation properties.

The Balancing Act: Formulation Dictates Fate

The magic of plastic wood lies in the precise formulation – the specific ratios and grades of polymers, the type and quality of wood fiber, and the carefully engineered additive package. A profile designed for budget fencing might prioritize high levels of recycled HDPE and filler, with a basic additive package. A premium decking board will likely use a higher proportion of virgin polymer or PP, top-quality hardwood fiber, advanced coupling agents, and robust UV/HALS stabilization, possibly with a protective co-extruded cap layer.

Conclusion: More Than Just Plastic and Sawdust

The raw materials for outdoor plastic wood profiles represent a sophisticated blend of chemistry, material science, and engineering. It’s not merely about mixing plastic bags with sawdust. The choice of polymer dictates fundamental weather resistance and structural behavior. The wood fiber provides crucial stiffness and eco-credentials but demands careful preparation. Finally, the often-overlooked additives are the unsung heroes, enabling processing, ensuring strong bonding, and crucially, protecting the composite from the relentless assault of sun, rain, temperature swings, and biological growth. Understanding these raw materials reveals why high-quality plastic wood can offer decades of low-maintenance service in the challenging outdoor environment, making it a truly resilient and sustainable building material. The next time you walk on a composite deck, remember the complex interplay of polymers, fibers, and stabilizers working together beneath your feet.